TINMORRY Filament TPU 1.75 mm, TPU Filament 3D Printing Materials for 3D Printer, 1 KG, 1 Spool, Black

Show on Amazon

Show on Amazon

Offer

£ 18.99

£ 4.49 | 1-2 Days

go to shop

Price trend

Product description

- Tips 1.Since TPU 95A filament is highly sensitive to humidity, it is recommeded to dry before use(Blast Drying Oven 70 8H) and keep sealed after use to achieve optimal printing performance. 2. Nozzle Temperature 210-240 , Bed Temperature 30-50 , Printing Speed 60mm s. Printing and Keeping Container's Humidity 20% RH (Sealed, with Desiccant)

- High Elasticity & Toughness With a Shore hardness of 95A, this filament offers high elasticity and exceptional toughness. It is ideal for creating flexible and bendable prints that require movement, such as phone cases, flexible toys, prosthetics, and other parts that need to stretch or deform.

- Premium Quality & Durable TINMORRY TPU 3D printing filament is very easy to use and has excellent adhesion to the hot bed without warping. With consistent dimensional tolerances and smooth extrusion, you can achieve accurate and stable printing size. In addition, with good wear resistance, chemical resistance and UV resistance, our TPU 95A filament is very suitable for various applications, especially those exposed to outdoor or harsh conditions.

- Vacuum Sealed Packaging All filaments are completely dried for 24 hours before packaging and packed in sealed vacuum bags with desiccant, which can easily keep the TPU 3D printer filaments in the best storage condition and free from dust or moisture before opening the vacuum sealed package.

- Wide Compatibility With a diameter of 1.75 0.05mm, our TPU filament is compatible with a wide range of 3D printers, and in particular is perfectly compatible with Bambu FDM 3D printer (AMS not compatible). From customised footwear to medical devices, this 1.75mm TPU 3D printer filament can be flexibly used in a variety of fields. If you have any questions while using TINMORRY filament, please contact us to get filament profile or download from GitHub.

You might also be interested in these 3d printer wires.

6Pcs 1.5M/4.9ft Stepper Motor Cables XH2.54 4Pin to 6Pin White Terminal Paralled Motor Wires for 3D Printer Stepper Motor

4 pin dupont connector of the driver side, compatible with RAMPS board and others.

Check price

YOUSU PLA Plus (PLA+) Filament 1.75mm,Professional High Toughness 3D Printer Filament,Dimensional Accuracy +/- 0.02mm 4x250g Pack A

5 Times Higher Toughness than PLA Yousu professional pla plus has greater impact resistance and rigidity, making it difficult to break.Satisfie your needs for printing functional parts with greater toughness while significantly raising the standard of routine printing.

Check price

3D Printer Filament Dryer, Sovol SH01 Filament Dehydrator Spool Holder, Dry Box for Keeping Filament Dry During 3D Printing, Compatible with 1.75mm, 2.85mm PLA PETG TPU ABS Material

Heating More Evenly - The unique design of the built-in fan in the box is based on the principle of modynamics of air, makes the filament heated more evenly. SH01 makes drying more efficient. Any questions about the product please feel free to let us know. Our technical support team will provide service as soon as we can

Check price

Stepper Motor Cable 4 Pcs 3D Printer Stepper Motor Cable XH2.54 Stepper Motor Connection Cable 4pin to 6pin for 3D Printers CNC Machines

Applicable Model - The 3D printer motor stepper motor cable is suitable for 42 series motors. Like B. 42BYG45040-24D, 42BYG45048-21D, 42BYG45034-24D, 42BYG45026-20D and other motors.

Check price

DollaTek 10 pcs/lot 70cm 3 Pin Female to Female Jumper Wire Dupont Cable designed for connecting components in 3D printers for Arduino main boards and module sensors

Made of high-quality materials, these jumper wires ensure stable and low-resistance connections, improving overall performance and efficiency in your electronic projects

Check price

ANYCUBIC Silk PLA Filament 1.75mm 1KG, Shiny Silk Gradient Tri-Color PLA Filament,Multicolor Material for 3D Printer, Dimensional Accuracy +/- 0.03 mm-Red Yellow Green

Wide Compatibility Made from natural corn and grain, which well-knowed for their recycle properties allowing the Anycubic Silk PLA Filament to degrades naturally in nature. Anycubic PLA Filament Compatible perfectly with most FDM 3D Printers that use 1.75MM filament on the market.

Check price

TINMORRY TPU Filament 1.75mm Combipack, 3D Printer Filament, 200g x 5 Spools, Black+White+Transparent Red+Blue+Green

Multiple Colours TINMORRY TPU 3D Printer Filament Combipack contains 5 spools, each spool contains 200g TPU filament, including popular colours Black, White, Transparent Red, Transparent Blue and Transparent Green.

Check price

VOANZO 3D Printer Stepper Motor Cable Double Z-Axis Motor Connector Accessories for CR-10/CR-10S Ender-3 Series 3D Printer

made of high quality materials. Durable, practical and precise design will ensure its practicality in high performance work.

Check price

Creality Ender PLA Filament 1.75mm 3D Printer Filament, 1kg Cardboard Spool (4.4lbs), Dimensional Accuracy +/- 0.03mm, Fit Most DIY Printer (Grey)

Neat Winding and Less Tangle Creality PLA filament 1.75mm adopt neat EPC automatic winding arrangement process to ensure the line tidy and less-tangle, avoiding possible breaks and thread breakage.

Check price

Jopto 5Pcs 1M Bipolar Stepper Motor Cable 4pin Nema17 Stepper Motor Cable Connection Cable Lead Wire Band 4pin Cable 42 Motor for 3D Printer CNC Machines

1M long stepper motor cable with 2 connectors, practical design for practicability.Perfect for NEMA 17 used in Reprap 3D Printers CNC Machines.

Check price

3 Pcs Metal Brush Small Wire Brushes for Cleaning 3D Printer Nozzle Cleaner Tool Copper Brush Brass Wire Toothbrush Masonry Brush Brass Brush Handle Hot End Cleaning Wire Bristle Welding Slag and Rust

Wide Application This copper cleaning brush is suitable for cleaning steel parts, machinery, paint stains, special corrosion, doors, floor tiles, and more.

Check price

OLYCRAFT 23PCS 3d printer accessories Nozzle Cleaning Tools Removal Tools Kit Includes Putty Knife Wire Brush Wire Flush Cutters Scraper Knife Diamond Files and Tweezers for Cleaning 3D Printer

Durable Material--Crafted from stainless steel, the putty knife, needles, wire flush cutters, diamond files, and tweezers boast a winning combination of flexibility, sturdiness, and long-lasting durability

Check price

Richer-R 3D Printer Wire Cutter 3D Printer Accessories, Side Cutting Nippers Wire Cutter Snips Shears Diagonal Pliers Tool Compact, Lightweight, Refined and Comfortable Handle Design

Application special high-speed tool steel, hardness reaches 58 degrees. The following wires can be easily cut soft metal below diameter of 1.6 mm, iron wire below diameter of 0.8 mm.

Check price

DollaTek 3D Printer Parts Touch Cable Extension Wire For CR-10 With Wrench Screw Bracket Connection Cable 3D Printer Accessor

Extension cables specifically designed for CR-10 3D printers, allowing for easy and convenient cable management.

Check price

Befenybay R18 Internal Size 10X15mm 1Meter Length Black Plastic Flexible Drag Chain Cable Wire Carrier Open Type for 3D Printer and CNC Machines (10mmX15mm-Outside Open)

The Cable Drag Chain is easy to install and repair, free movement, low noise, wear-resistant, high-speed movement

Check price

2 Pcs Small Brass Brush, Copper Wire Toothbrush, Mini Wire Brush Metal Rust Brush Tool Wire Brush for Cleaning Welding Slag and Rust, 3D Printer Nozzle Cleaning

Material The bristles are made of copper wire and the handle is made of plastic.

Check price

FOGAWA 12Pcs Small Wire Brush Set Brass Wire Brush Metal Rust Remover Brushes Stainless Steel Metal Brush for Cleaning Rust 3D Printer Nozzle Welding Slag Dirt with Curved Handle

Comfortable using - Wire brushes for cleaning which shares the same shape with toothbrush, providing comfortable touch which is much alike the touch of common toothbrush, without damaging metal work surfaces or fine features.

Check price

10PCS Brass Brush, Small Metal Brush Mini Wire Brushes for Rust Removal Cleaning Welding Slag Sink 3D Printer Cleaning Brushes

Package Include You will receive 10pcs of brass brush, with a length of 17cm 6.69 inches each. And brush head size is 3.5 x 1cm 1.37 x 0.39in.

Check price

nuosen Wire Cutter, Craft Wire Precision Electrical Cable Cutter Cutting Plier Side Snips Flush Cutter Diagonal Pliers Cutting Pliers Tool for Coil Making, Home DIY Jewelry

DURABLE DEIGN - Forged-teel contruction for durability. Rut-reitant finih for greater protection.

Check price

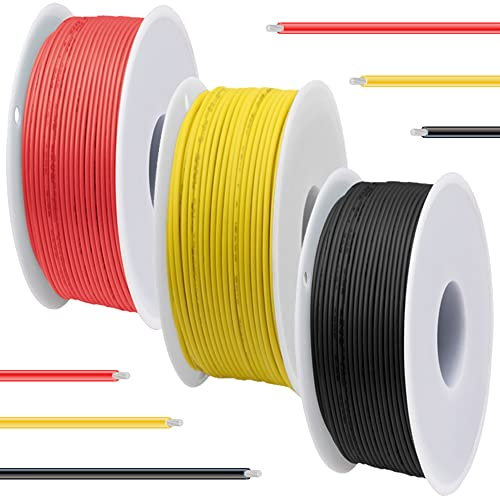

DAOKAI 20 Gauge Silicone Wire 600V 20 AWG Stranded Tinned Coated Copper Wires 3 Color (Black, Red, Yellow) 7m/23ft Each Electrical Cable Hook Up Wire Kit for 3D Printer, Model Car

Application Widely use for LED strip, electronics, electrical appliance and equipment, transformer, RC model and motor lead wire connection.

Check price